CENTAFLEX & CENTAMAX COUPLINGS

Trans Tech stock a wide range of Centa Couplings, specifically the Centaflex A, Centaflex H, Centaflex K, Centaflex X and Centaflex DS couplings. Centamax elements are also available on ex-stock basis.

Other models such as Centax, Centaflex E and Centaflex SEC are supplied on order basis.

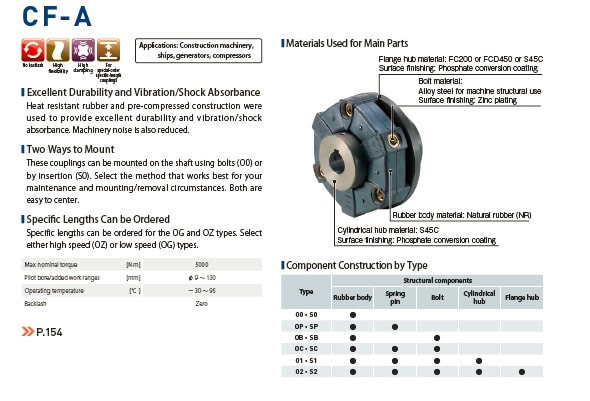

Centaflex A Couplings

Centaflex A couplings also known as CF-A couplings are 5 way flexible. Their rubber element is resistant to heat and the pre-compressed construction provide high vibration absorption capacity and reliability. These couplings require no maintenance. The rubber parts suffer no wear, providing long useful life with no dirt produced by rubber particles.

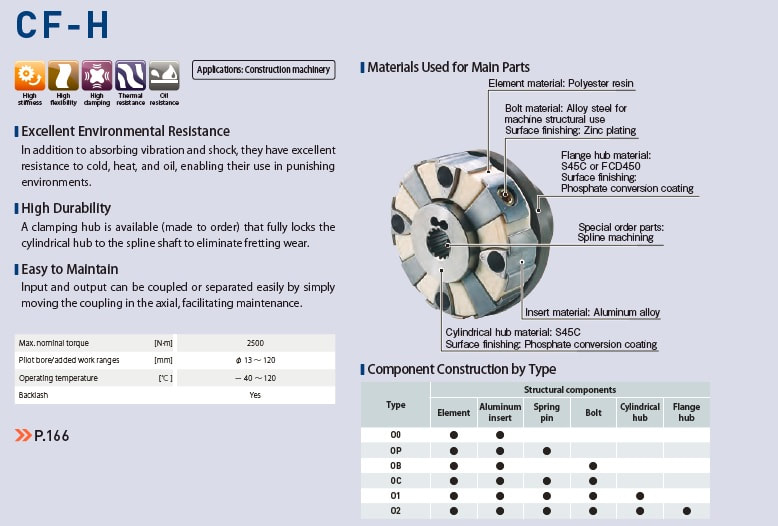

Centaflex H Couplings

Centaflex H couplings are torsionally stiff and allow high rotational speeds. They are specially designed for diesel hydraulic drives. Centaflex H dampens torsional vibrations and shocks and compensates high axial as well as moderate radial and angular misalignments. They are very durable, oil-resistant and can withstand high temperatures inside housings between engines and hydraulic pumps.

Centaflex H couplings are highly used in excavators of well known brands such as Hyundai, Volvo, Doosan.

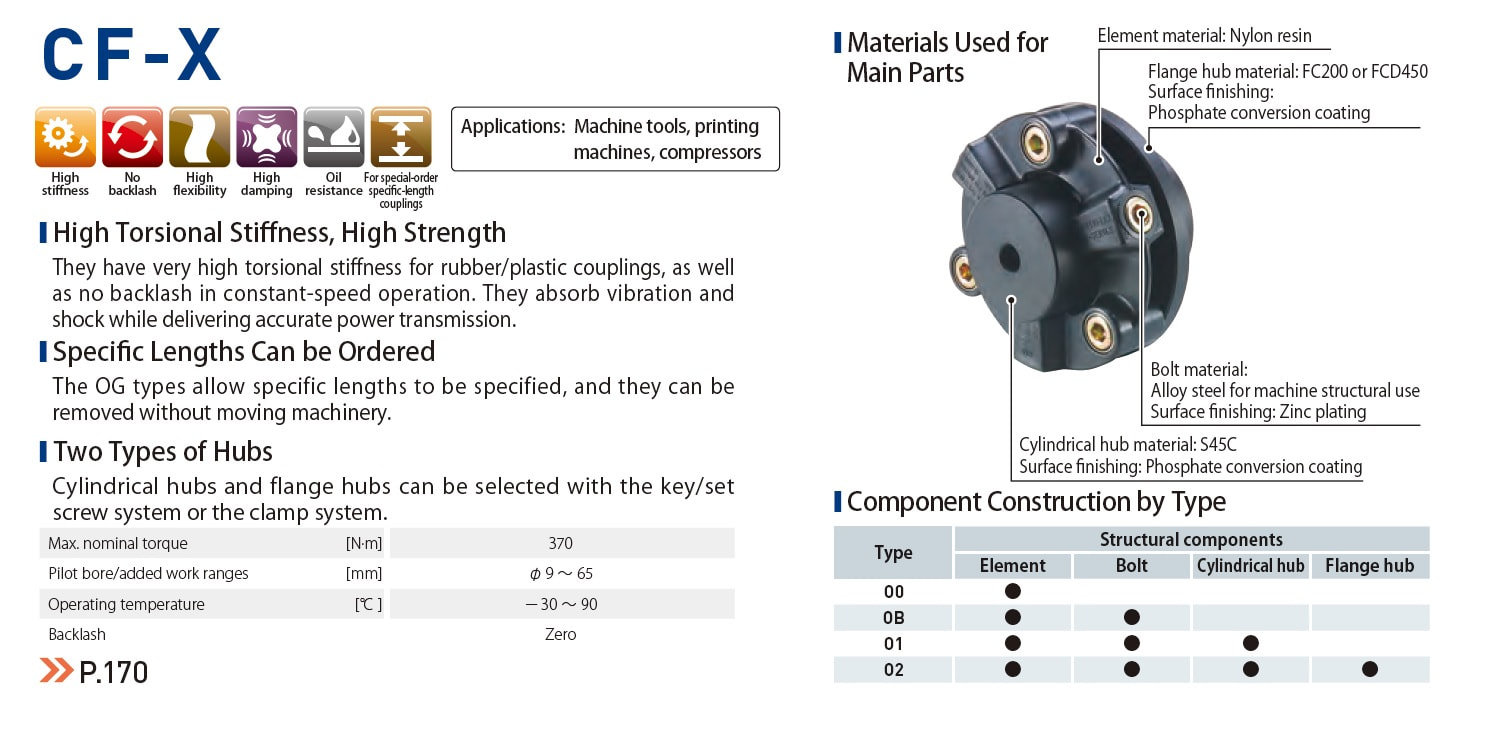

Centaflex X Couplings

Centaflex X couplings are well known for high torsional stiffness and high strength. They have no backlash and are oil resistant.

The hubs can be ordered in two versions: Cylindrical hubs and flange hubs. The spacer lengths can also be customized as per end user requirements.

The Centaflex X elements are made of Nylon resin material and the hubs are made of S45C carbon steel.

The hubs can be ordered in two versions: Cylindrical hubs and flange hubs. The spacer lengths can also be customized as per end user requirements.

The Centaflex X elements are made of Nylon resin material and the hubs are made of S45C carbon steel.

Centamax Couplings

Centamax coupling elements are highly elastic couplings used primarily in Diesel engine applications such as compressors, ship propulsion, generator sets, pumping sets. They have been highly successful in difficult applications for torque transmission as they are free of backlash, protect the diesel engine from dangerous slip loads, require no maintenance and are designed for blind fitting.

We have in stock standard sizes of Centamax elements; larger sizes and special versions can be ordered. For the complete set with hubs and flange the complete part number/drawing is essential.

Centaflex K Couplings

Centaflex K couplings are rigid and very torsionally stiff couplings. They enable hydraulic pumps and similar equipments to operate below critical speeds without torque vibrations. They are used mainly in equipments with low to medium power range such as excavators, cranes, dumpers, forklifts, concrete mixers, tractors.

We have in stock certain sizes of Centaflex K couplings and flanges. For certain special versions drawings are required.

Centaflex DS Dual Stage Couplings

Centaflex DS are dual stage couplings which are highly used by diesel engine manufacturers such as Volvo Penta, Yanmar etc. The coupling has the capabilities to absorb torsional vibrations in low rpm range between 500 to 1000 rpm and then acts as a stiffer jaw coupling for high rpm speeds. Centaflex DS design is simple and compact: the rubber elements are heat resistant and the coupling has sufficient internal ventilation to dissipate heat.

Centaflex DS couplings are primarily used in the following applications:

Centaflex DS couplings are primarily used in the following applications:

- Between diesel engine and flange mounted gear

- Between diesel engine and independently mounted gear

- Auxiliary drives with high idling rpms, such as clutches, fire fighting pumps